DTS is proud to announce that Prowave is our new sales partner in Taiwan.

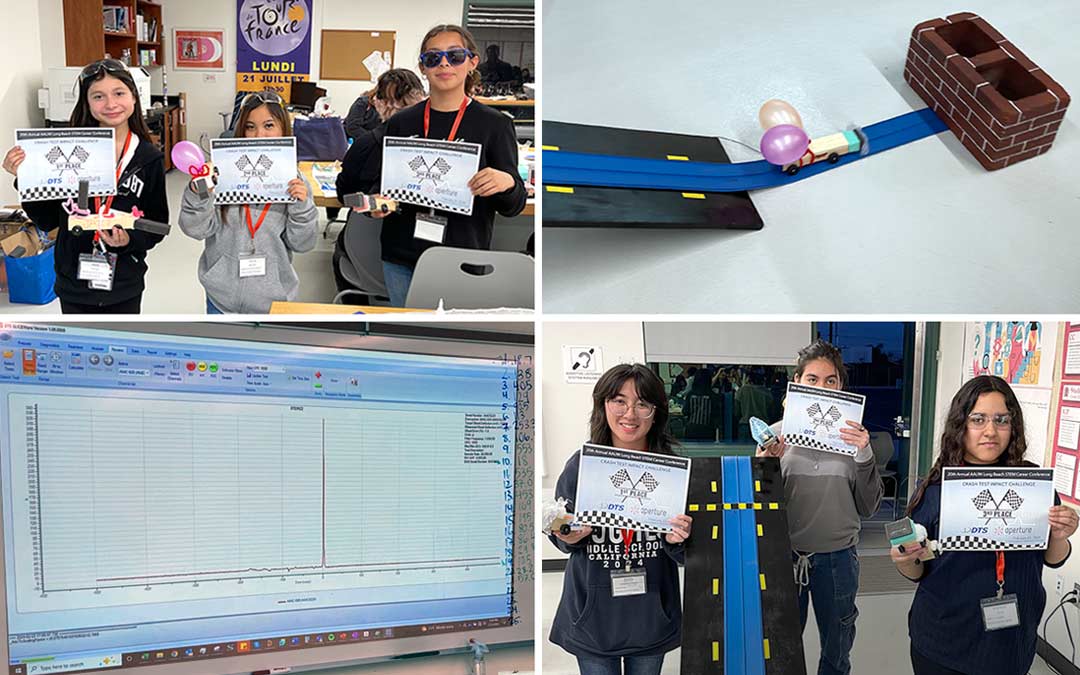

AAUW STEM Career Conference 2024

How Would You Design a ‘Smart & Safe’ Bumper?

DTS and Aperture LLC will find out how 7th and 8th-grade girls engineer their smart bumpers in a hands-on workshop at the 20th Annual AAUW STEM Career Conference in Long Beach, CA. The conference hosts 250 local students and features eleven female STEM professionals describing their career paths, plus hands-on career-related activities for the students.

The 20th Annual AAUW Long Beach STEM Career Conference will be held on Friday, February 23, 2024 at the Sato Academy of Mathematics and Science. The STEM Career Conference has been organized since 2003 by AAUW Long Beach and is currently held at the Sato Academy of Mathematics and Science, with the assistance of over 60 adult volunteers plus 20 Sato Ambassadors who help welcome the girls to their campus. Attendance is by invitation only. AAUW Long Beach selects Title I LBUSD middle and K-8 schools for participation in the conference. The attendees are then recruited by teachers or counselors at their school. Attendance is limited to girls since women are still underrepresented in STEM careers and the mission of AAUW is to advance equity for women and girls. Through January 2024, 3135 girls have participated in the event.

The 2024 workshops, with hands-on activities, will feature the following STEM careers: Aerospace Engineer, Architect, Environmental Engineer, Manufacturing/Biomechanical Engineer, Medical Imaging Technologist, Medical-Surgical Nurse, Optometrist, Software Developer, Speech-Language Pathologist, and Structural Engineer.

The mission of AAUW is to advance gender equity for women and girls through research, education, and advocacy. Super excited to partner with AAUW and Aperture to invest in the future . . . which starts with awareness, opportunity, and action!

Related Articles

DTS New Sales Partner – PROWAVE

DTS Named Best Place to Work in SoCal

Best Companies Group named DTS one of the Best Places to Work in Southern California

Congratulations on Your Retirement, DTS Co-Founder Steve Pruitt!

After 33+ years at DTS, Steve Pruitt, co-founder and Chief Sales & Business Development Officer, has retired.

About DTS

Top Products

Quick Links

Corporate