Military Vehicle Testing

MILITARY VEHICLE TESTING

THINK DTS

- Ultra-small, embedded data acquisition and sensors

- Rugged, modular systems

- Outstanding worldwide technical support 24/7/365

RECOMMENDED DTS PRODUCTS

MILITARY VEHICLE TESTING

ONBOARD, RUGGED DATA ACQUISITION SYSTEMS

The Challenge:

- Field testing military vehicles for durability, ride & handling and off-road performance

- Rugged, often remote test environments or in-situ data collection

- Complicated test set-ups, including long cable runs that can cause issues with noise

- Synchronizing high-speed cameras, trigger, power and communication

- Power considerations, especially for long duration test cycles

The Solution:

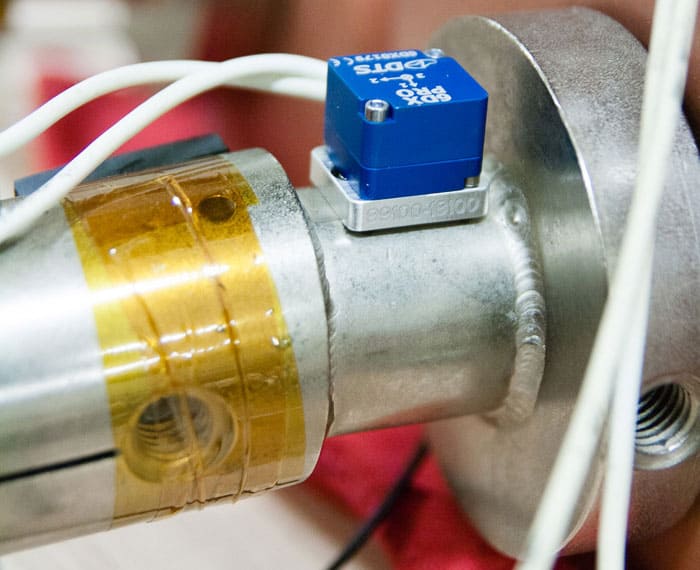

- Ultra-small, rugged DTS data acquisition systems and sensors

- Miniature, standalone systems can be placed onboard near point of interest

- Modular, user-configurable for a variety of applications and test requirements

- Low power draw, systems designed to record for minutes to days

- Complete line of ancillary accessories, plus extensive sensor support

- Store in place reliability, data writes directly to non-volatile flash memory

- Trusted complete solution provider, experts in automotive safety testing

For more information contact sales@dtsweb.com

“Occupant safety is only one aspect of vehicle safety and testing.”