WHY DTS

DTS specializes in Rugged, Miniature Data Acquisition Systems (DAQ), Data Loggers and Sensors for Vehicle Crash Testing, Injury Biomechanics, Blast Testing, Flight Testing and many more applications.

10 Top Reasons to Choose DTS Data Acquisition Systems & Sensors

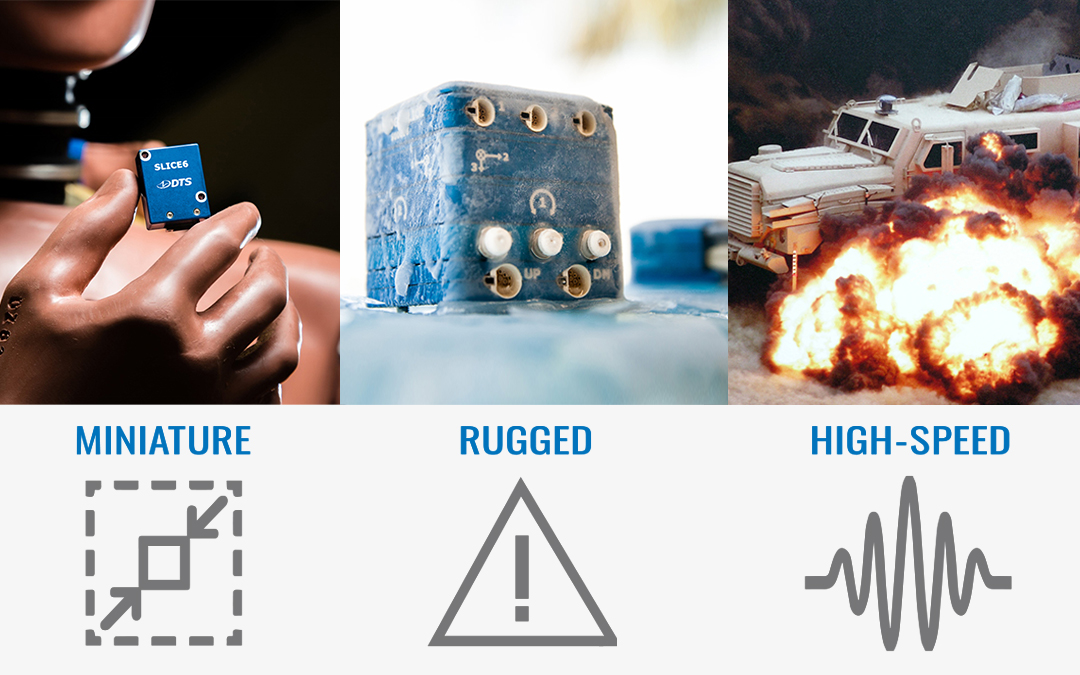

1. Miniature. DTS data acquisition systems and sensors are ultra-small and designed to be embedded on or in test articles, without altering test dynamics.

2. Rugged. Highest shock rating available. Engineered to be reliable in even the most extreme test environments, from crash and blast testing to aerospace applications.

3. High-Speed. DTS DAS features full signal conditioning plus user-configurable sampling rates from 10 – 1M samples per second per channel.

4. SWaP-C Optimized. Size, weight, power, and cost optimized. DTS systems are COTS (commercial off-the-shelf) which makes them cost-effective and readily available with short lead times.

5. Onboard Recording & Streaming. Remote reliability, data writes directly to non-volatile flash memory, plus real-time streaming options available.

6. Standalone or Networked. DTS DAS can work standalone, networked, and as part of a centralized solution — including FTI systems.

7. Versatility & Flexibility. Modular systems are designed to be customized to support required features, functions and channel count.

8. Reduced Cabling & Connectors. Small and rugged enough to be positioned near the sensors, DTS DAS reduces set-up times, cost, and potential issues caused by complicated long cable runs.

9. Eliminates Slip Rings. Ideal for collecting vibration, strain and stress data on rotating applications without the need for slip rings.

10. Worldwide Technical Support. DTS global Technical Centers and online Help Center support customers technical needs 24/7/365.

Top Reasons to Choose DTS DAQ & Sensors

1. Miniature. DTS data acquisition systems and sensors are ultra-small and designed to be embedded on or in test articles, without altering test dynamics.

2. Rugged. Highest shock rating available. Engineered to be reliable in even the most extreme test environments, from crash and blast testing to aerospace applications.

3. High-Speed. DTS DAS features full signal conditioning plus user-configurable sampling rates from 10 – 1M samples per second per channel.

4. SWaP-C Optimized. Size, weight, power, and cost optimized. DTS systems are COTS (commercial off-the-shelf) which makes them cost-effective and readily available with short lead times.

5. Onboard Recording & Streaming. Remote reliability, data writes directly to non-volatile flash memory, plus real-time streaming options available.

6. Standalone or Networked. DTS DAS can work standalone, networked, and as part of a centralized solution — including FTI systems.

7. Versatility & Flexibility. Modular systems are designed to be customized to support required features, functions and channel count.

8. Reduced Cabling & Connectors. Small and rugged enough to be positioned near the sensors, DTS DAS reduces set-up times, cost, and potential issues caused by complicated long cable runs.

9. Eliminates Slip Rings. Ideal for collecting vibration, strain and stress data on rotating applications without the need for slip rings.

10. Worldwide Technical Support. DTS global Technical Centers and online Help Center support customers technical needs 24/7/365.

https://dtsweb.com/wp-content/uploads/2024/07/Why_DTS_Rugged_Miniature_HighSpeed.jpg