In Iraq and Afghanistan underbody blasts from improvised explosive were the largest cause of injury for U.S. troops. In order to help make troops safer, the U.S. Army first needed a highly specialized test dummy that would allow them to gather the right data in a blast test.

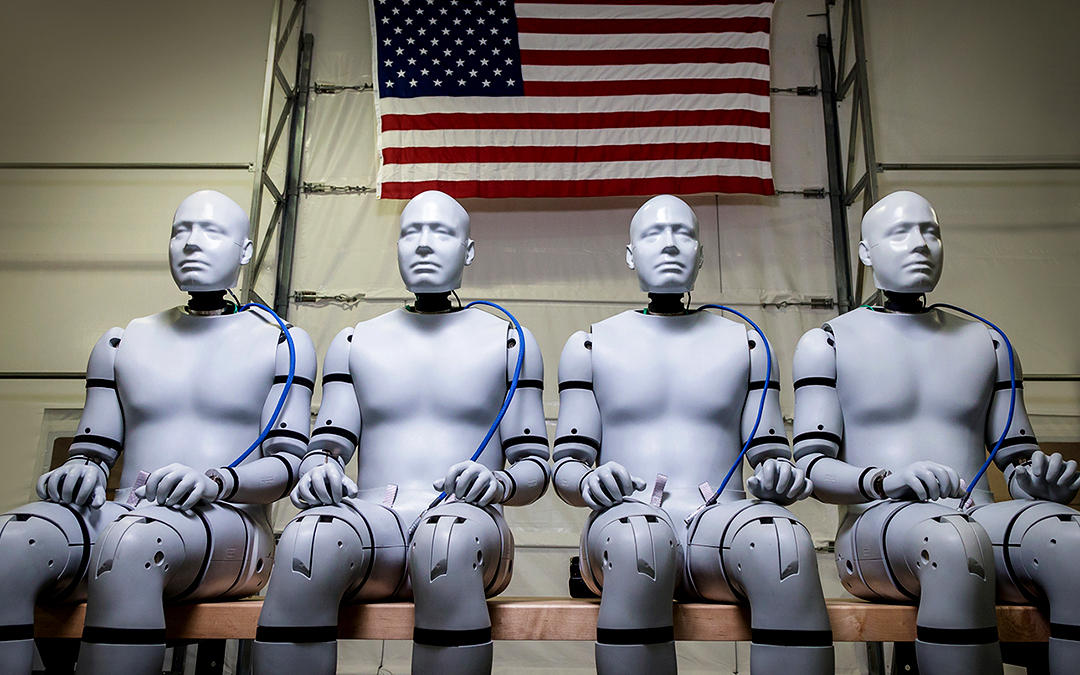

That specialized blast test dummy is now a reality and is known as WIAMan, or Warrior Injury Assessment Manikin. WIAMan is specifically designed for military use in underbody blast testing of vehicles to validate vehicle design and safety features engineered to protect warfighters. As stated in a recent news post on soldiersystems.net1:

“WIAMan represents the most human-like surrogate yet to provide insight on improving military ground vehicle systems and identify protection mechanisms that reduce the likelihood and severity of warfighter injuries.”

Developed in partnership with the U.S. Army, DTS, and top universities, who were responsible for extensive injury biomechanics research, the WIAMan blast manikin measures vertical loads. A blast impact comes from below the occupant. Automotive crash test dummies are designed to measure only frontal or side impacts, which is why development of WIAMan was critical. DTS was the prime contractor and built both the manikin and the SLICE6 data acquisition system and then integrating them.2

This large volume of data is processed by analytical experts from DEVCOM (U.S. Army Combat Capabilities Development Command) “to provide reliable injury assessment and analysis.”1

The WIAMan software analysis tool used is called AMANDA, or the Analysis of Manikin Data. And on Feb. 2, 2022, AMANDA received a final stamp of trust in quality and accuracy when it was accredited by the U.S. Army Test and Evaluation Command for use in live fire test and evaluation.

“The WIAMan data acquisition system takes samples from an event at a rate of approximately 200,000 samples a second, and the typical event takes a couple seconds, so we’re talking around 400,000 data samples — an incredible amount of data,” said Jacob Ehlenberger, AMANDA software developer. “When you load that into AMANDA, all subject matter experts have to worry about is looking at the results. AMANDA automates the entire process, bringing complex analysis to the hands of experts so they can focus on their domain of excellence.” 1

AMANDA also integrates filtering methodology, developed by Aaron Alai, a DAC signal processing scientist, to ensure sensor data does not reflect extraneous noise that could lead to incorrect injury prediction.1

The data produced by WIAMan, once analyzed, helps the Army to more accurately measure soldier risk and evaluate trade-offs in vehicle design. Ultimately this means reducing the likelihood and severity of warfighter injuries.

“Simply put, insight from AMANDA saves lives.”1

Resources

- https://soldiersystems.net/2022/05/17/army-injury-assessment-tool-receives-stamp-of-accreditation/

- https://www.aerodefensetech.com/component/content/article/adt/features/articles/27963

Related Articles

DTS New Sales Partner – PROWAVE

DTS is proud to announce that Prowave is our new sales partner in Taiwan.

DTS Named Best Place to Work in SoCal

Best Companies Group named DTS one of the Best Places to Work in Southern California

Congratulations on Your Retirement, DTS Co-Founder Steve Pruitt!

After 33+ years at DTS, Steve Pruitt, co-founder and Chief Sales & Business Development Officer, has retired.

SUBSCRIBE FOR DTS NEWS & UPDATES

YES! Sign me up