After 33+ years at DTS, Steve Pruitt, co-founder and Chief Sales & Business Development Officer, has retired.

U.S. Army Deliveries & First-Ever Test with 12 WIAMan

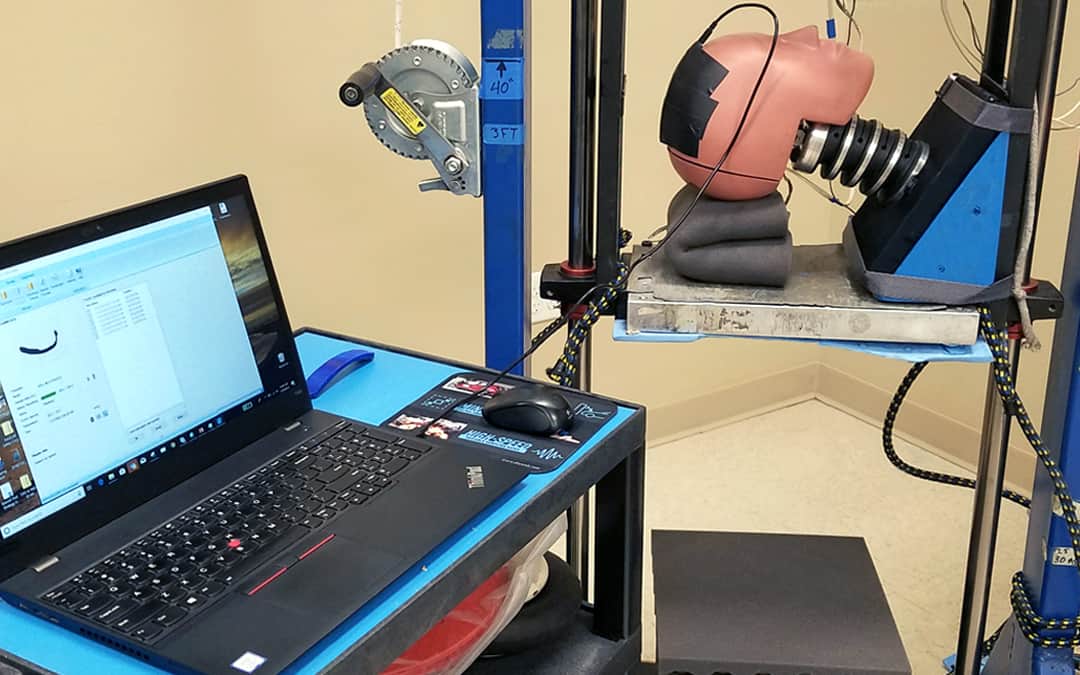

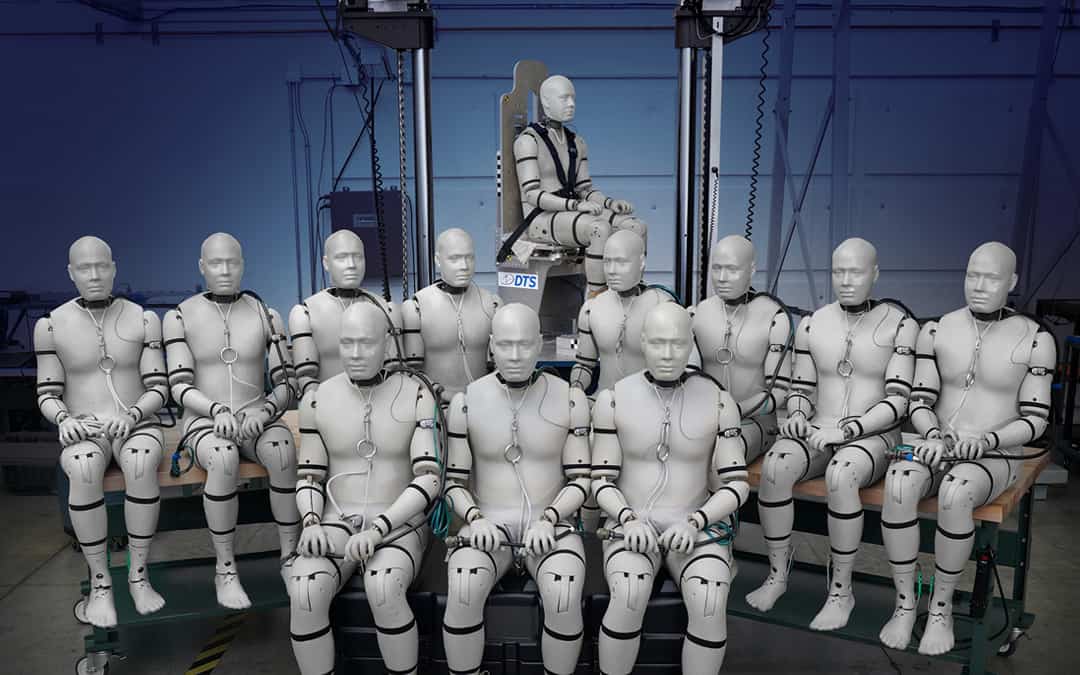

The latest shipment of five additional WIAMan Blast Test Manikins was delivered to the U.S. Army in December. Just prior to that shipment marked the first time that twelve WIAMan were gathered and operated together as a full-capacity test system. The new WIAMan, plus 2 development and 5 production manikins, were all gathered in DTS’s ATD Lab located in Seal Beach, CA for system validation testing and some ‘family’ photos.

“This was our first chance to test the External Distributor at full capacity. There literally have never been 12 WIAMan in existence, let alone all in one place,” said Tamer Abubakr, ATD Systems Manager at DTS. The test involved connecting all 12 WIAMan to a single Distributor, which manages test communication commands. As anticipated, the test was a success.

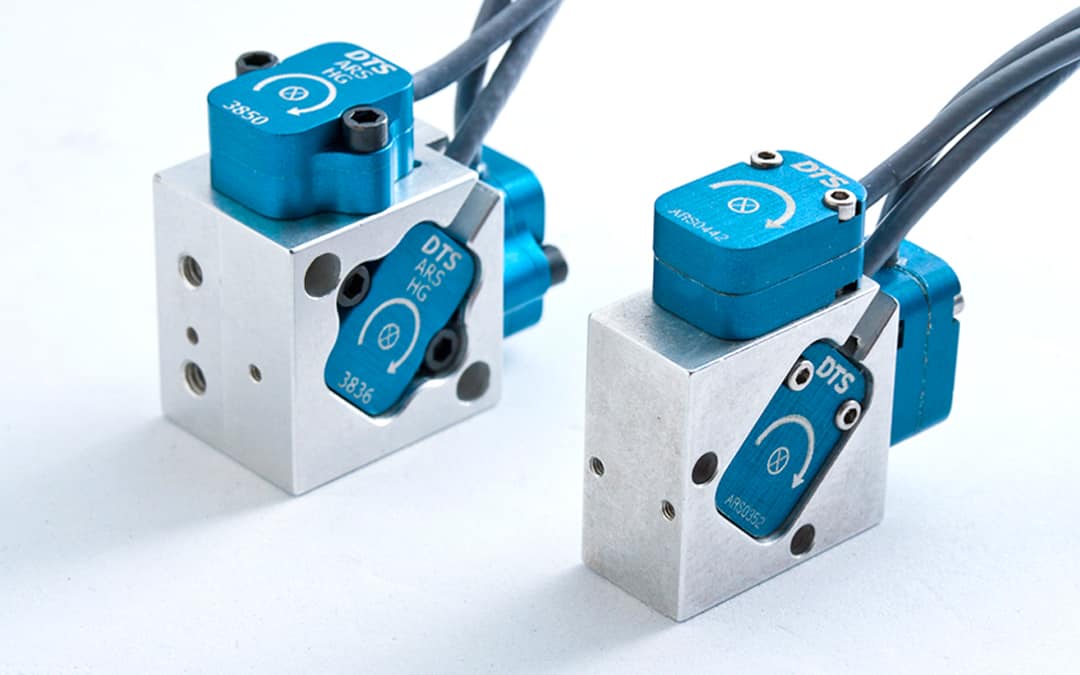

DTS’s involvement with the WIAMan project includes building the actual ATD (anthropomorphic test device), as well as the SLICE6 data acquisition system embedded inside and ancillary equipment like the External Distributor. Each WIAMan supports up to 156 sensor (data) channels. “A single exit cable from each ATD gets plugged into the External Distributor to manage communication, status, trigger, IEEE 1588 synchronization, and backup power if needed,” explained Abubakr.

U.S. Army WIAMan Blast Manikins were gathered at the DTS ATD Lab in California for a ‘family’ photo and the first opportunity to test some of the support equipment at full capacity with 12 WIAMan.

Tamer then went on to explain in general terms how a blast test is set-up. First the miniature data recorders and sensors are embedded inside each WIAMan. The manikins are then positioned in the test vehicle and an exit cable from each ATD is run to the External Distributor. The Distributor sends commands to and from each ATD, and it’s secured in a blast bunker many meters away from the actual blast site. While one External Distributor can ‘talk’ to up to 12 WIAMan at a time, the official Command Center is miles away and manages the complete test set-up and trigger which is transmitted via fiber optic cables to the Distributor and then to each WIAMan.

DTS is prepared to deliver additional WIAMan to the U.S. Army as part of the contract, which includes up to 40 WIAMan in total. An official 700-page WIAMan accreditation report is currently under review by the U.S. Army, which will make WIAMan the first ever accredited ATD for use in under body blast testing.

DTS has been part of the WIAMan development team from the initial concept phase, including being chosen as the prime contractor to the U.S. Army. The Warrior Injury Assessment Manikin represents one of the most advanced collaborations of injury biomechanics research, engineering, manufacturing and testing. “WIAMan is the most hi-tech, biofidelic soldier surrogate in existence. It’s all about the data and each underbody blast (UBB) test provides more data to help keep our warfighters safer,” added Abubakr.

All 12 WIAMan were connected to the DTS External Distributor which manages communication, status, trigger and IEEE 1588 synchronization for the underbody blast testing. This marks the first time that a dozen WIAMan existed and could be gathered in one place.

Related Articles

Congratulations on Your Retirement, DTS Co-Founder Steve Pruitt!

DTS Named Best Place to Work for 4th Year

The OC Business Journal named DTS one of the “Best Places to Work” for four consecutive years.

Tim Kippen DTS Co-Founder Retires – Congratulations!

Congratulations Tim on your retirement from DTS after more than three decades of vision, passion, dedication and hard work! You will be greatly missed.

SUBSCRIBE FOR DTS NEWS & UPDATES

YES! Sign me up