Congratulations to DTS Co-founder, Tim Kippen, on his induction to Cal Poly Pomona’s Engineering Hall of Fame

Are EV’s Safer in a Crash?

Electric vs. Gas: Which Vehicles are Safer?

Navigating New Features, Functions, and Global Safety Requirements

Electric and hybrid electric vehicles (EVs/HEVs) frequently outperform internal combustion engine vehicles in safety ratings, driven by design advantages such as a low center of gravity, larger crumple zones, and integrated electronic speed controls. These features enhance crash energy management and vehicle stability.

However, the shift to electrification introduces new technical challenges, particularly in crashworthiness validation and post-crash safety. High-voltage systems pose risks to occupants and emergency responders, necessitating rigorous testing under FMVSS305 and similar global standards.

Why EVs Can Be Safer:

- Lower center of gravity: Due to battery placement, reducing rollover risk.

- Larger crumple zones: No engine up front allows better energy absorption in frontal crashes.

- Advanced safety features: Many EVs come with the latest ADAS (Advanced Driver Assistance Systems).

- Remote speed control: Some EVs allow setting and monitoring top speeds remotely — ideal for teen drivers or fleet monitoring.

- Higher safety ratings: Several EVs (like the Tesla Model Y or Ford Mustang Mach-E) score top marks in IIHS and NHTSA crash tests.

Potential Risks with EVs:

- High-voltage shock: Post-crash electrical isolation is critical to occupant and first-responder safety

- Fire risk: While rare, battery fires can be harder to extinguish than gasoline fires.

- Thermal runaway: Heat buildup can lead to explosions in severe impacts.

- Heavier weight: EVs tend to be heavier, which can increase injury risk to occupants in lighter vehicles during collisions.

- Unexpected acceleration: EVs can accelerate quickly, catching some drivers off guard, especially inexperienced drivers

The Federal Motor Vehicle Safety Standard FMVSS305 focuses on post-crash safety for EVs. The standard mandates a minimum level of electrical isolation between the high-voltage system and the vehicle’s chassis. The goal is to isolate any electrolyte spillage from propulsion batteries to ensure occupants and first responders are protected from high-shock sources, especially following a crash.

Meeting New Testing Requirements

With new technology comes the need for new testing protocols and equipment. In response to customer requests, DTS introduces the new FMVSS305 high-voltage recorder for testing EV and Hybrid new energy vehicles (NEVs). The DTS FMVSS305 allows for remote measurements, making it ideal for use with the 301 static rollover system.

FMVSS305 High-Voltage Recorder

The DTS FMVSS305 is a high-voltage isolation measurement system for electric and hybrid vehicle testing. It provides a safe and reliable way to capture battery and drive system voltages up to ±1,200-volts. The unit is designed to be used standalone or can be seamlessly integrated into TDAS or SLICE data acquisition systems via DataPRO Software. For more information, click Learn More.

The bottom line, based on all the data and safety testing, there’s no absolute winner between EVs and gas vehicles. Electric vehicles are generally as safe or safer than gas-powered vehicles, but as the fine print always says . . . it depends on the model and type of crash.

Related Articles

Engineering Hall of Fame Inducts Tim Kippen

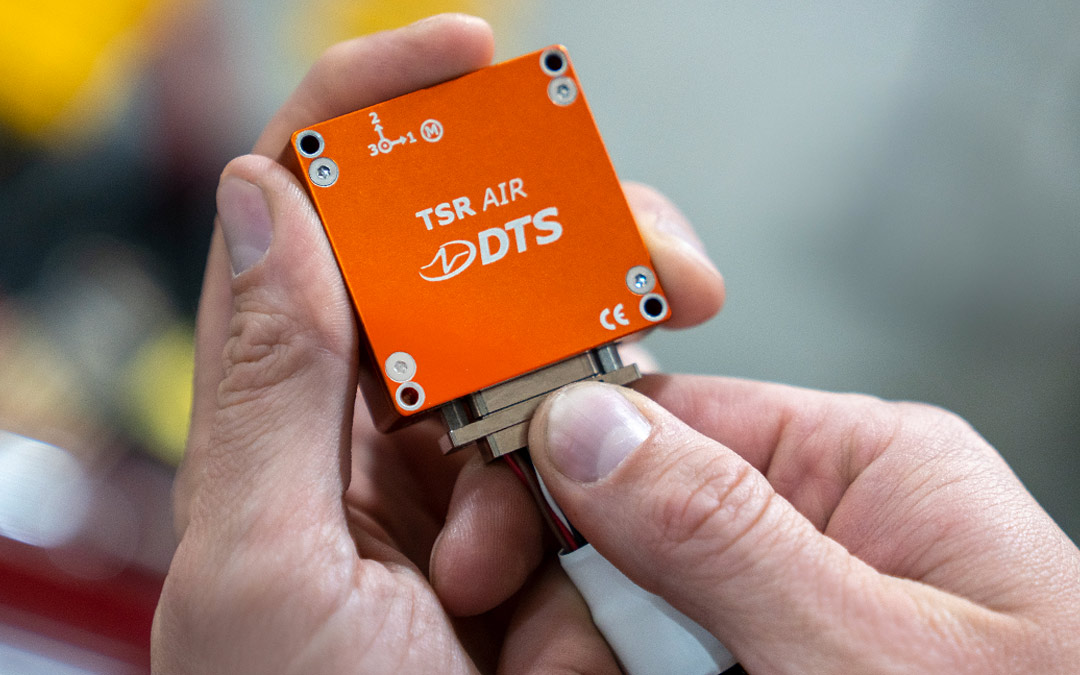

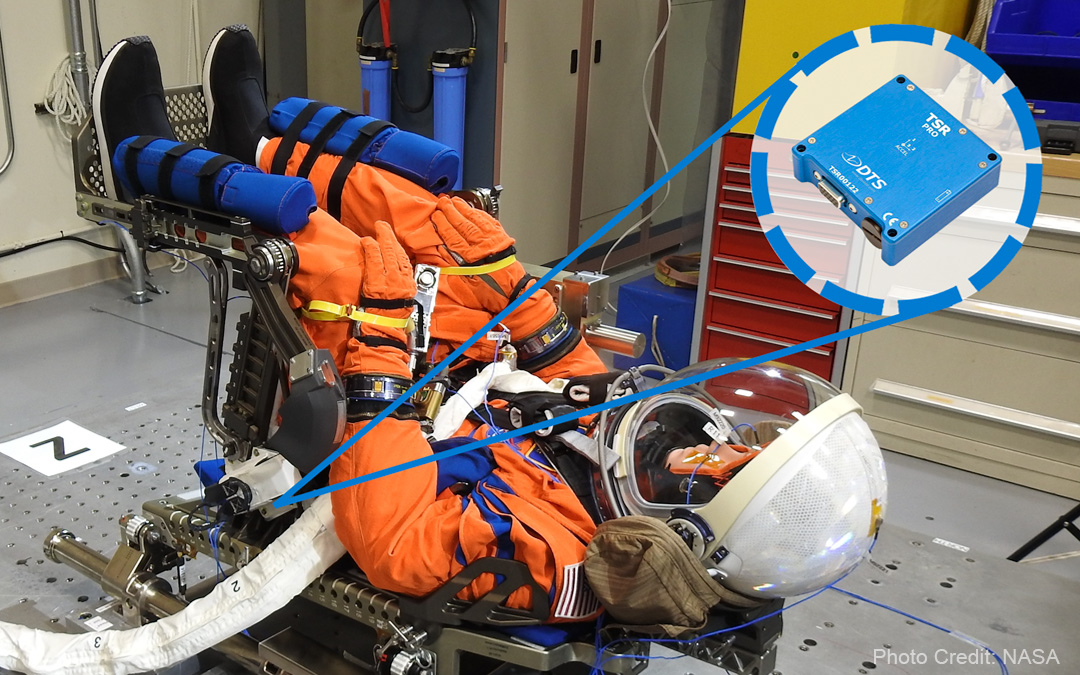

DTS Application Spotlight: Satellite Transportation Monitoring

How the TSR AIR data logger is helping ensure the safe transit of high-value assets.

DTS Innovation Room 2024

Join us at the DTS Innovation Room Oct 22-23 Automotive Testing Expo North America