Mars Mission

MARS MISSION

THINK DTS

- Standalone, ultra-small, embedded data acquisition systems

- Rugged, modular, SWaP-optimized

- 24/7/365 outstanding worldwide technical support

RECOMMENDED DTS PRODUCTS

NASA MARS SAMPLE RETURN

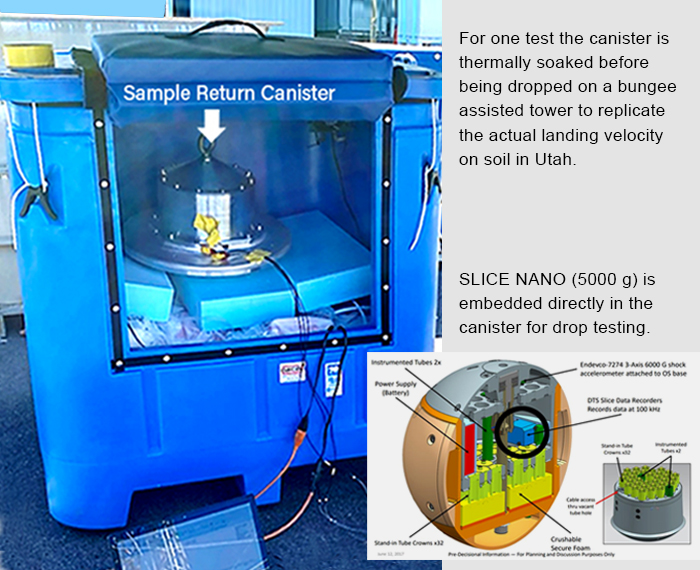

DROP TESTING TO HELP ENSURE SAFE DELIVERY TO EARTH

The Challenge:

- Part of the Mars mission will include returning a variety of rock samples to Earth

- NASA and JPL needed to drop test the prototype return canister that will house the samples

- Ability to withstand landing speeds of 100 mph when it free falls and lands in the desert of Utah

- Data acquisition systems and sensors able to operate in extreme environmental conditions

- Limited space and weight constraints for test instrumentation

- Standalone data acquisition that can meet strict power considerations

The Solution:

- DTS miniature, rugged data acquisition systems and sensors

- Advanced vibration and shock tolerant features

- SWaP-optimized for Size, Weight and Power

- Standalone system, runs on battery

- Collect physical measurements including: acceleration, vibration, strain & temperature

- Ability to record for extended periods of time in remote locations

- Data writes to non-volatile memory for safe retrieval

Video & Images Courtesy of NASA and JPL

For more information contact sales@dtsweb.com

“This is an unprecedented experiment and an exciting endeavor for the future of mankind and beyond.”