When testing matters. Lightweight Data Acquisition Solutions for Heavy-duty Testing. 10 Top Reasons to Use DTS Data Acquisition Systems and Sensors.

SLICE PRO DISTRIBUTOR – New Test Device Manages Over 800 High-Speed Data Channels

Streamlining Crash Testing: New Test Device Manages Over 800 High-Speed Data Channels

Crash testing plays a crucial role in advancing occupant and pedestrian safety worldwide. As part of that pursuit, modern crash tests now collect vast amounts of high-speed data, a trend on the rise for decades. Originally, most of the crash data collected directly supported U.S. and Global NCAP test requirements. Today, a significant amount of additional data is being collected to advance finite element modeling or crash simulations.

Collecting vast amounts of data requires more complex data acquisition solutions. DTS, a leader in data acquisition systems for dynamic testing, has developed the SLICE PRO DISTRIBUTOR to simplify this complex landscape. The new test device is a centralized hub that manages signal integration, communication, and power distribution for multiple crash test dummies and up to a remarkable 820 data channels in a single vehicle.

Managing hundreds of data channels during a crash test is a significant challenge. The SLICE PRO DISTRIBUTOR acts as a central nervous system for the test setup. Event and status signals from each connected system are isolated internally and then integrated to provide a single event and status signal for the entire system.

“With the increasing complexity of vehicle safety testing, DTS’s goal is to simplify testing. Whether it’s 8 channels or 800, it’s all about reliability and repeatability from the test setup to the final data download,” says Chad Ivan, automotive applications manager for DTS. “The SLICE PRO DISTRIBUTOR is a game-changer for automotive testing.”

Instead of managing multiple connections to a control PC, external switch, or wireless unit, all communication functions, diagnostics, system status monitoring, and data downloads are managed through a single connection. The SLICE PRO DISTRIBUTOR is compatible with a range of DTS products and can be easily integrated into existing test environments.

Key features of the SLICE PRO Distributor include:

• Compact, crashworthy enclosure

• Gigabit Ethernet communications protocol that enables all 8 ports to simultaneously download data without throttling

• Supports a mix of up to 820 channels of in-dummy and SLICE PRO DAS

• Higher primary input power range of 36-56 VDC

• The ability to support up to two POWER PRO battery units for redundant power backup

There are ongoing discussions that debate whether physical crash testing is needed with today’s sophisticated finite element models (FEMs). As long as it’s law and physical testing is required to validate and improve modeling, crash testing will continue. The vast amount of test data collected is also advancing new vehicle designs and improving future testing. The bottom line is that more data is a global win for safety.

DTS is a leading provider of data acquisition systems and sensors for automotive safety testing, aerospace, injury biomechanics, and other demanding applications. DTS is committed to providing innovative solutions that help its customers improve product safety and performance.

Related Articles

WHY DTS

BLOG Template BACKUP – DO NOT OVERWRITE

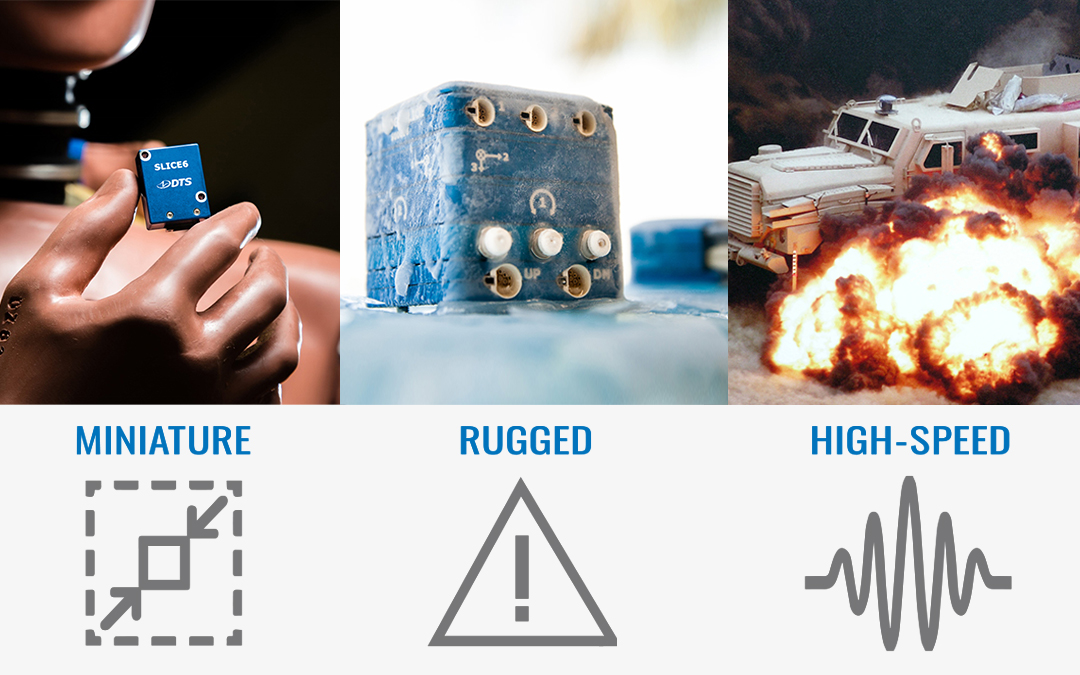

Seal Beach, CA. (Mar. 2020) - Diversified Technical Systems, Inc. specializes in rugged, miniature data acquisition systems and sensors for critical testing. Based in Southern California, DTS technical centers and sales partners worldwide support critical testing in a...

BLOG Template to USE for all new posts

Seal Beach, CA. (Mar. 2020) - Diversified Technical Systems, Inc. specializes in rugged, miniature data acquisition systems and sensors for critical testing. Based in Southern California, DTS technical centers and sales partners worldwide support critical testing in a...