Bicycles

BICYCLES

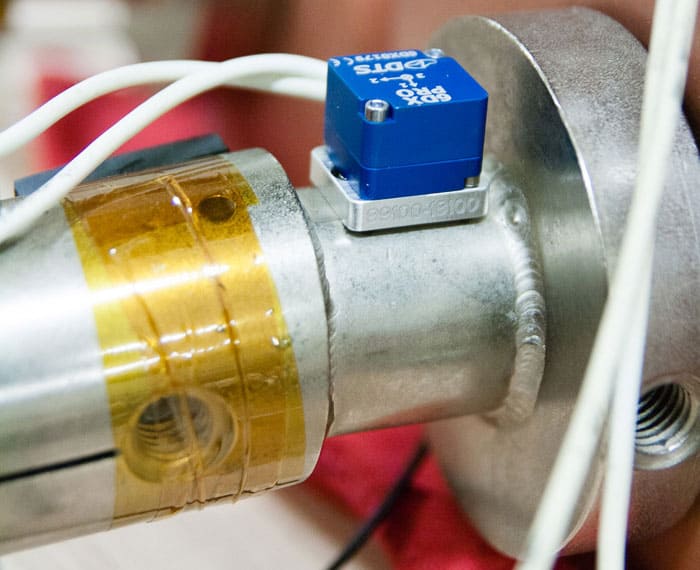

THINK DTS

- Rugged data acquisition

- Ultra-small, low power, doesn’t alter test dynamics

- Outstanding worldwide technical support 24/7/365

RECOMMENDED DTS PRODUCTS

BICYCLE TESTING

ROAD TESTING PERFORMANCE & STRUCTURAL INTEGRITY

The Challenge:

- Equipment manufacturers need to field test performance cycles

- Measuring acceleration, speed, strain and displacement in situ

- Bulky test equipment that adds mass (up to 5+ gk) or alters test dynamics & CG

- Large systems that require rider to wear in backpack

- Shock and vibration tolerant systems

- Environmental extremes including temperature, moisture, altitude

- Cables that can get tangled or alter test dynamics

- Configurable systems to support lab and field testing

- Long duration tests

The Solution:

- Ultra-lightweight DTS data acquisition systems (less than 200 g)

- Data recorders small enough to attach directly to the frame, forks or rider

- Positioning the DAS near sensors, eliminates long cable runs, improves data quality

- Low power, simple battery solutions for extended record time

- Modular (3-30+ channels), quick and easy set-up in the field

- Supports a variety of sensors, plus built-in sensor options

- Store in place reliability, data writes directly to flash memory

- Easy, intuitive for software set-up, viewing and data export

For more information contact sales@dtsweb.com

“Being able to position the DAS at the point of interest is advancing our understanding what’s really happening with both the equipment and the athlete.”