DTS announces Crisel as its newest international Sales Partner. Crisel will focus on two of DTS’ innovative products, SLICE6 AIR and TSR AIR, for aerospace and defense testing. Based in Italy, Crisel is a leading provider of high-technology solutions, equipment, and components.

Miniature Data Recorder Helps NASA

A new Dynamic Kinematic Recorder (DKR) is being developed by Diversified Technical Systems (DTS), as part of a Phase 2 Small Business Innovation Research Award to help NASA advance flight crew safety.

“We worked with NASA to understand the pressures and forces astronauts experience during launch and re-entry phases,” said Mike Beckage, co-founder and CTO of DTS. “Unlike a crash or blast event that literally lasts milliseconds, flight crews experience intense forces over an extended time period.”

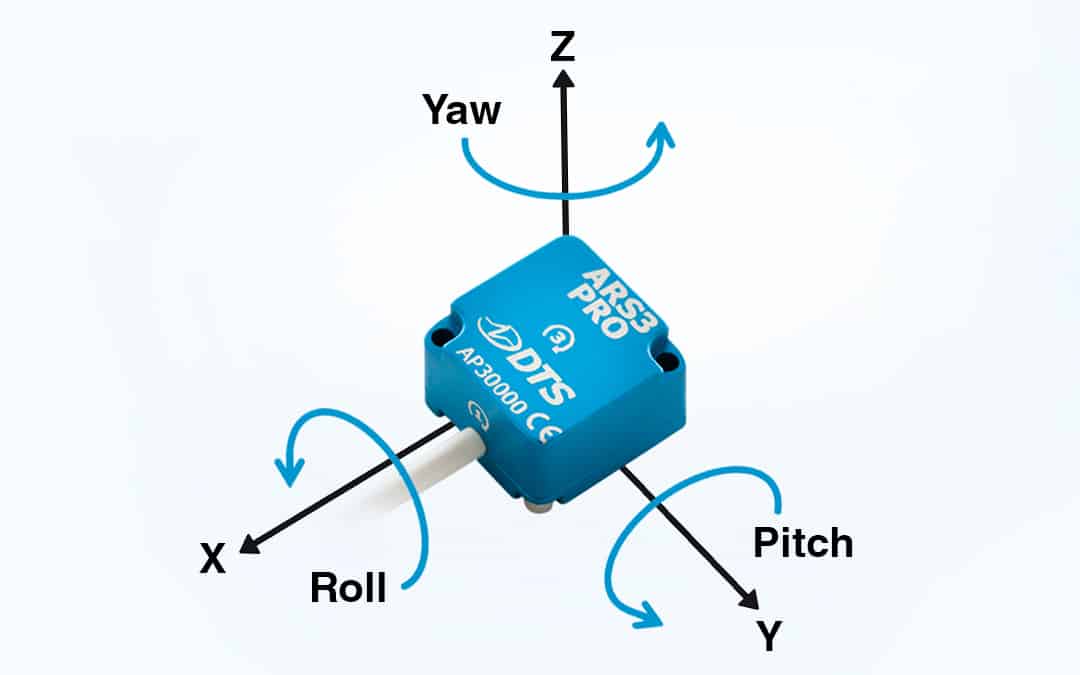

The gravitational forces exerted upon an astronaut during launch are roughly 3 times the gravitational pull on Earth. Reentry, which is faster than the speed of sound, creates additional stress and forces on the body. Each DKR will feature six degree of freedom (6DOF) sensing and onboard memory, which means all data will be stored in non-volatile memory. The data gathered with the DKR will be used to develop new protective gear, like restraints and seating.

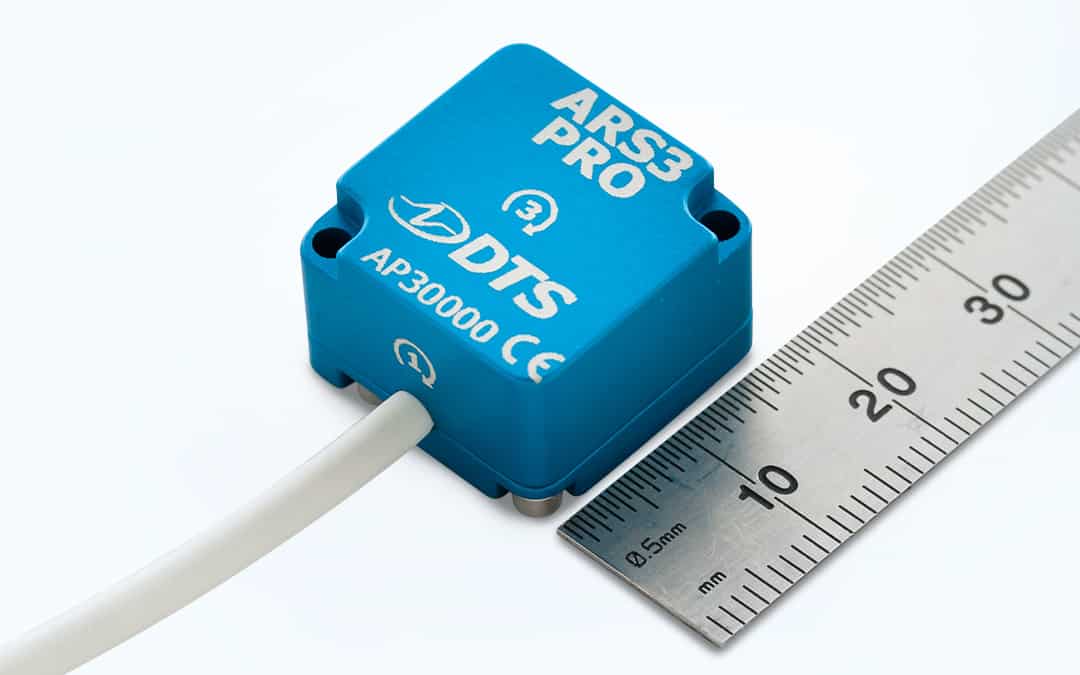

Collecting field data without altering test dynamics is a challenge, especially when human subjects are involved and in extreme environments such as space. The innovative DKR recorder is rugged enough to withstand intense forces, yet small enough to overcome the size and mass concerns with payload heading into space.

“For Phase 1 we came up with the concept for a physical device and made iterative improvements meeting NASA’s need. We proved the size, power and performance requirements. For Phase 2 we are working towards a final design and form-factor in anticipation of real-world testing and evaluation. The DKR needs to fit on, or in, a helmet, record for an extended time period, and not interfere with any gear or movements the astronauts need to perform during their mission,” added Mike.

The Small Business Innovation Research program awards funding to U.S. small businesses to support the development of new technology that can be commercialized. DTS has received numerous SBIR awards based on 30 years of experience developing innovative data recorders and sensors used around the world for safety testing in aerospace, military, and automobile industries.

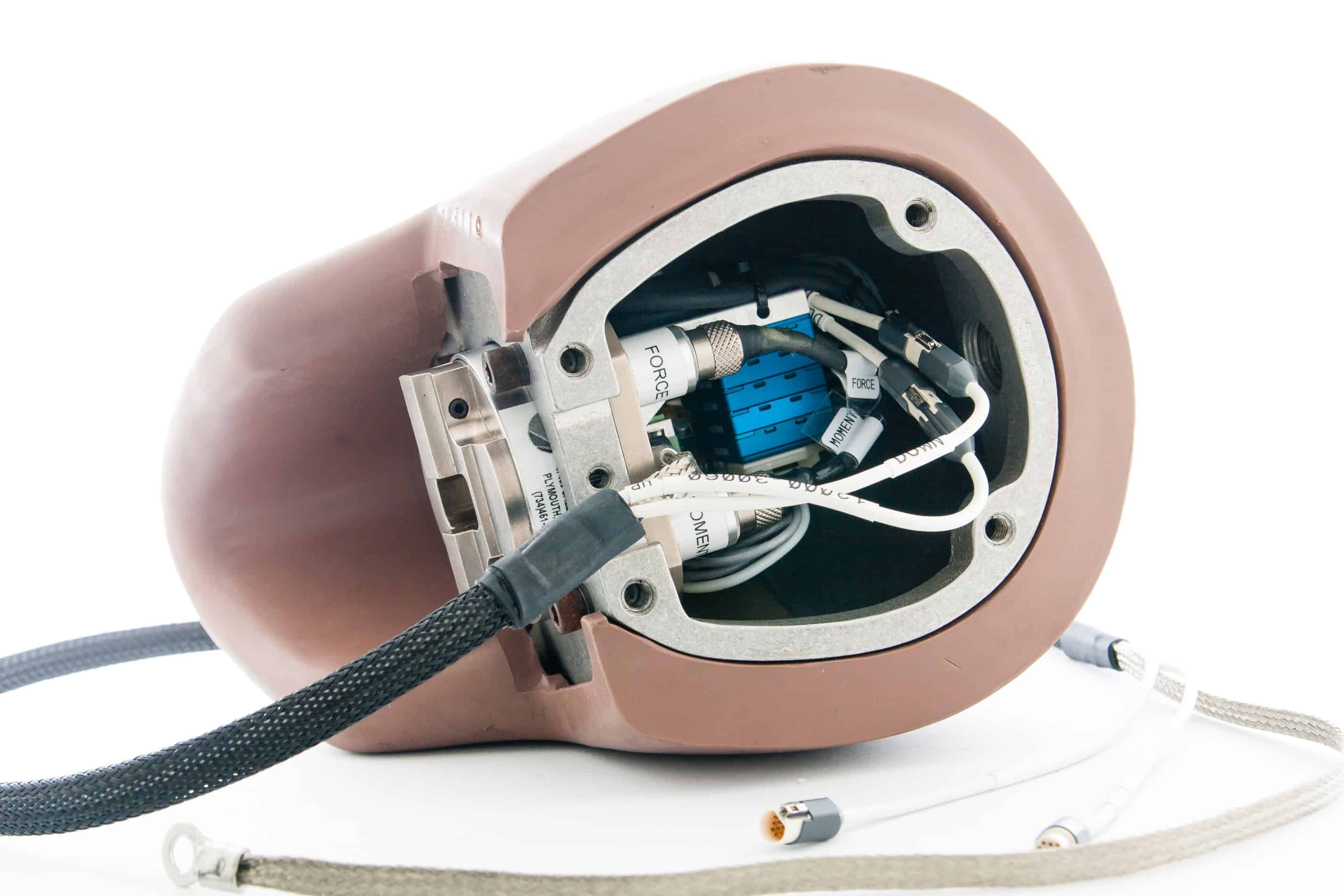

The miniature Dynamic Kinematic Recorder DTS is developing for the NASA will measure forces that astronauts may experience during launch and re-entry phases.

The Dynamic Kinematic Recorder (shown as a prototype on the communication cap) will collect data that will be used to improve astronaut safety.

The miniature Dynamic Kinematic Recorder DTS is developing for the NASA will measure forces that astronauts may experience during launch and re-entry phases. The unit (shown as a prototype on the communication cap) will collect data that will be used to improve astronaut safety.

Related Articles

DTS New Sales Partner – CRISEL

DTS 2022 Highlights

We are proud to announce that a DTS TSR PRO data logger is traveling beyond the moon onboard Artemis 1, to help capture vital acceleration and vibration data that can help improve astronaut safety on the upcoming crewed mission, Artemis II.

To Boldly Go Where No TSR PRO Has Gone Before…the Moon

We are proud to announce that a DTS TSR PRO data logger is traveling beyond the moon onboard Artemis 1, to help capture vital acceleration and vibration data that can help improve astronaut safety on the upcoming crewed mission, Artemis II.

SUBSCRIBE FOR DTS NEWS & UPDATES

YES! Sign me up

About DTS

Top Products

Quick Links

Corporate