For a 6th consecutive year, Diversified Technical Systems (DTS), headquartered in Seal Beach, California, was named as one of the Best Places to Work in Orange County.

Physical Data: The Engine Behind Digital Twins

The Role of Physical Data in Building Intelligent Digital Twins

In the fast-moving world of digital twins, the accuracy and reliability of virtual models still depend on one critical factor: physical data. The success of any digital twin hinges on two essential elements – the quality of real-world data it’s built on and the ability to access that data in real-time.

DTS, a California-based leader in high-performance data recorders, is at the forefront of this digital twin revolution. Renowned for its miniature, rugged data acquisition systems (DAS) and sensors, DTS provides solutions that seamlessly bridge the gap between physical systems and their digital counterparts. From automotive and aerospace to military and industrial sectors, organizations around the world are leveraging DTS hardware to elevate their digital twin capabilities.

DTS solutions deliver high-density, precision measurements that go beyond shock, vibration, force, and temperature – enabling digital twins to be built on accurate, comprehensive datasets.

Advanced capabilities like real-time data streaming enable continuous monitoring and instant feedback for digital twin models. This is especially valuable in high-stakes environments that demand immediate analysis and decision-making — such as flight testing and military defense operations. The SLICE6 AIR onboard recorder from DTS supports real-time streaming to ensure digital twins stay synchronized with the current state of their physical counterparts.

By integrating DTS hardware into digital twin development, organizations can anchor their virtual models in precise, real-world data. This accuracy enhances the fidelity and usefulness of digital twins, allowing teams to make informed decisions, optimize system performance, and predict outcomes with confidence. As the digital twin ecosystem evolves, DTS continues to be a trusted partner, delivering the high-performance tools needed to build reliable, real-time virtual representations of physical systems.

The SLICE6 AIR onboard data acquisition unit features real-time streaming capabilities, making it ideal for supporting digital twin modeling.

Related Articles

DTS Named Best Place to Work for 6th Year

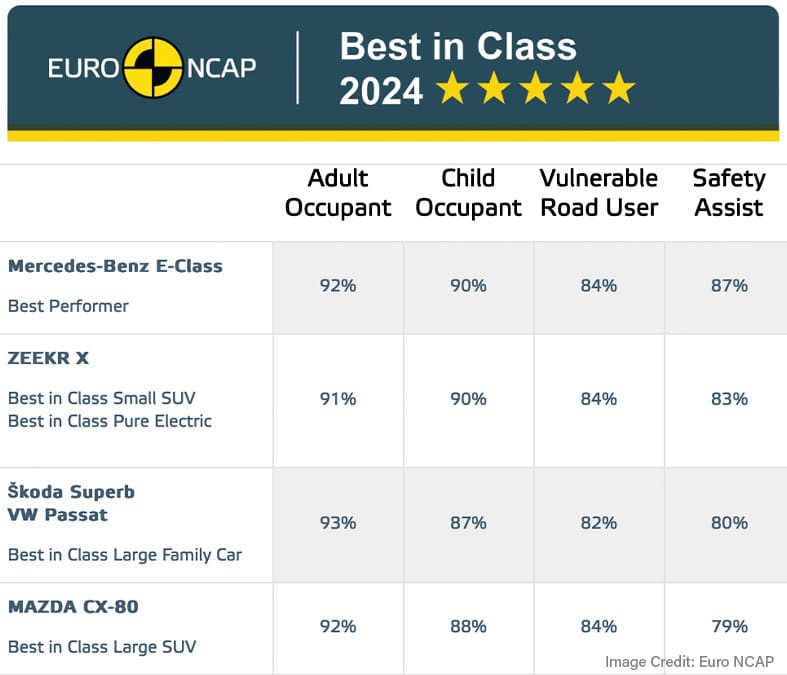

Are EV’s Safer in a Crash?

DTS, a leading provider of crash test solutions, announces the release of a new high-voltage recording device specifically designed for FMVSS305 testing of new energy vehicles (NEVs).

Engineering Hall of Fame Inducts Tim Kippen

Congratulations to DTS Co-founder, Tim Kippen, on his induction to Cal Poly Pomona’s Engineering Hall of Fame

Quick Links